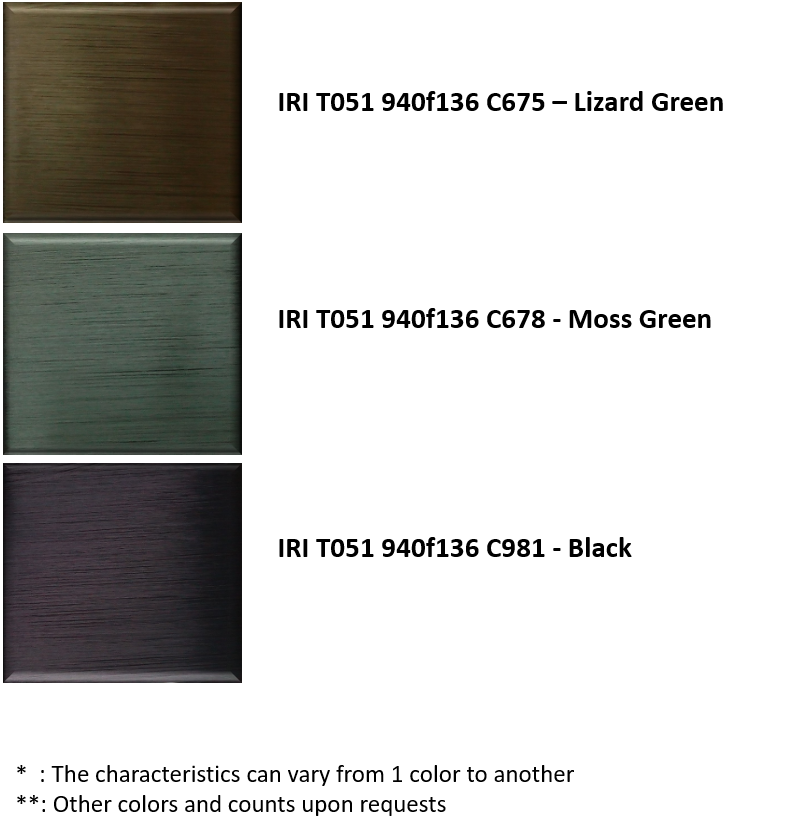

Nexis Fibers offers special spun dyed fibers functional in NIR spectrum for producing a camouflage garments, backpacks, vests, heavy-duty belts, tactical equipment.

Military forces use a camouflage materials that attempt to minimize the contrast between objects and their environment over the near infrared region of the electromagnetic spectrum.

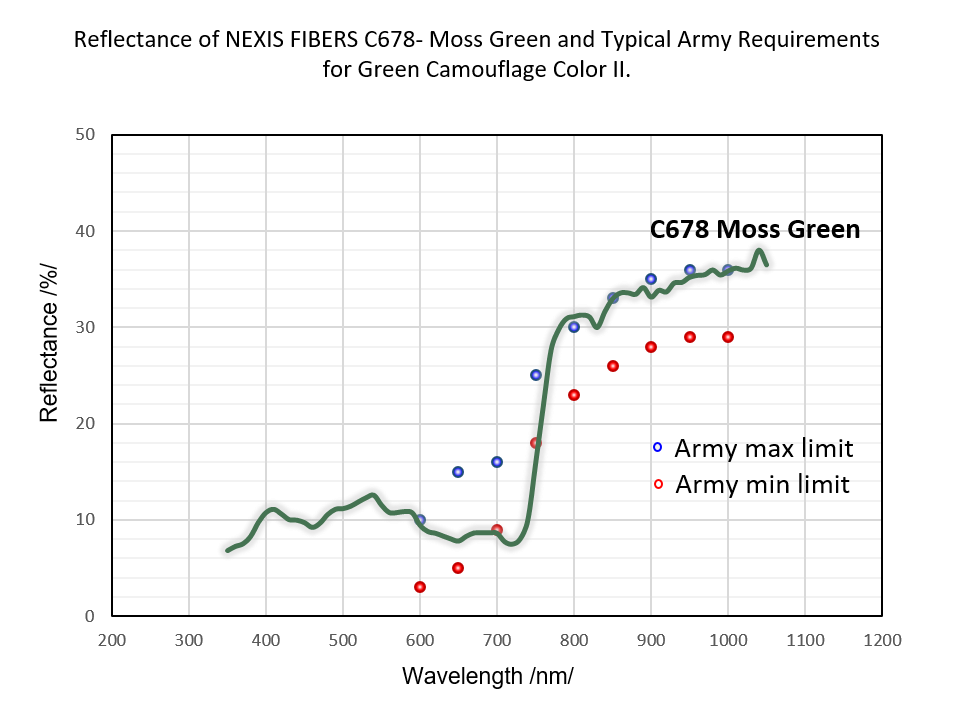

In practice, it means applying colors and materials which trying to mimic natural or artificial backgrounds. Each military nation has adopted its own colors with specific reflectance and wavelength. Colors often include khaki, green, brown or black.

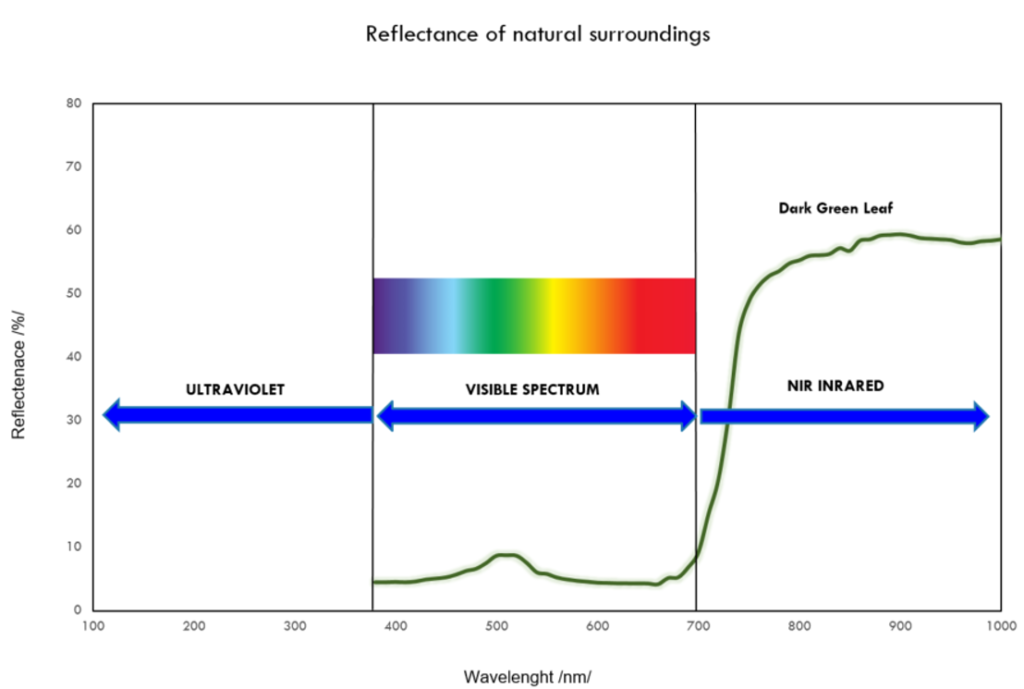

Infrared (IR) light is electromagnetic radiation with a wavelength longer then that of visible light.

It is measured from the nominal edge of visible red light at 0,74 micrometers (mm) and extending conventionally to 300 (mm). These wavelength correspond to a frequency range of approximately 1 to 400Thz, and include most of the thermal radiation emitted by objects room temperature.

Microscopically, IR light is typically emitted or absorbed by molecules when they change their rotational vibrational movements.

Near Infrared red (NIR) range is between 700-1200nm.

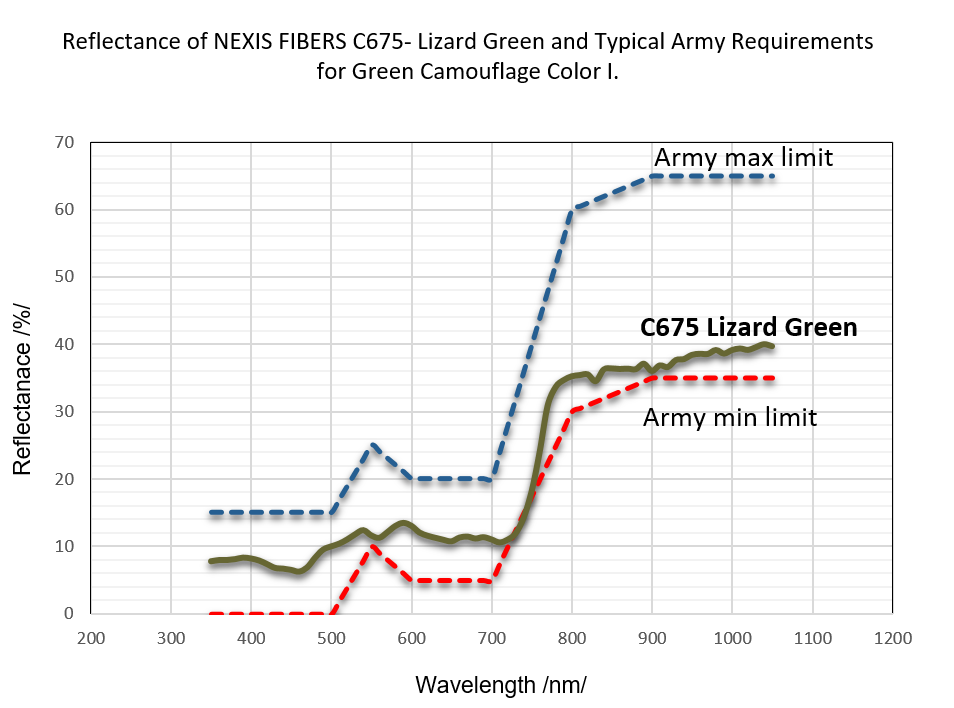

Plants tend to have a small increase in reflectance at around 520nm, which is responsible for the green coloration. Then in range of about 670-780nm, the reflection increases steeply. At longer wavelengths the reflectance remains fairly constant until about 1300nm.

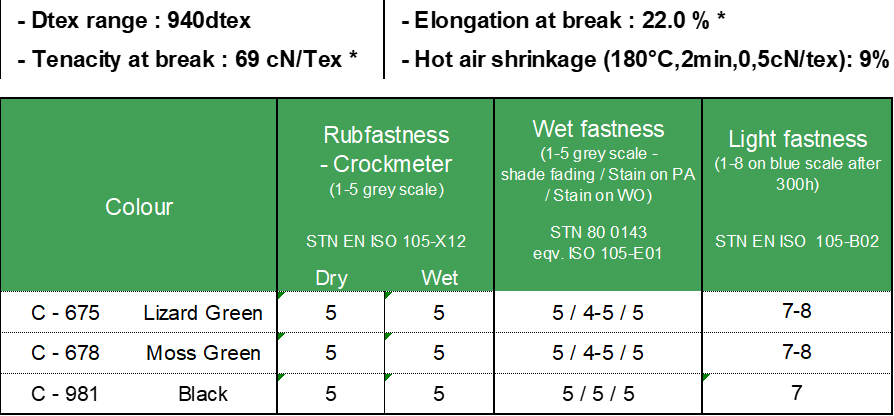

Green shades must duplicate the „chlorophyll increases“. General shape of Nexis Fibers IRI colors follows the reflectance profile of green leaves.

Main benefits

Yarns for Ropes & Nets

Yarns for airbags & weaving applications

Yarns for tyres & MRG

Special polymers

Twisted & Air-Jet Textured Yarns

Nexis Fibers a.s.

Chemlonská 1

066 12 Humenné

Slovakia

Phone: +421 57 787 3145

Fax: +421 57 7722 650

E-mail: info@nexis-fibers.com

Product Safety: productsafety@nexis-fibers.com